MITUTOYO - Vision Measuring Machine with Micro-Form Scanning Probe MiSCAN Vision System| JSR GROUP

MiSCAN Vision System

A thoroughbred microscopic-form measurement system, developed from coordinate measuring machine and vision measurement system technology

Highly accurate autonomous scanning covering from micro-form to large workpieces

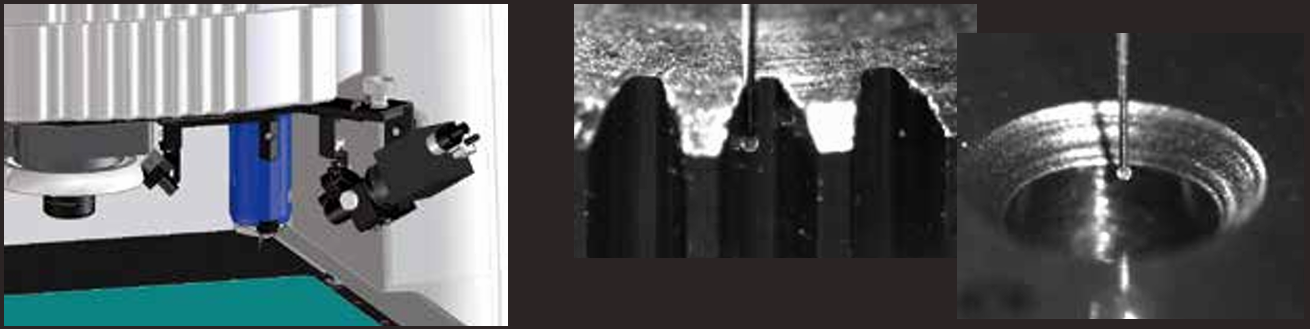

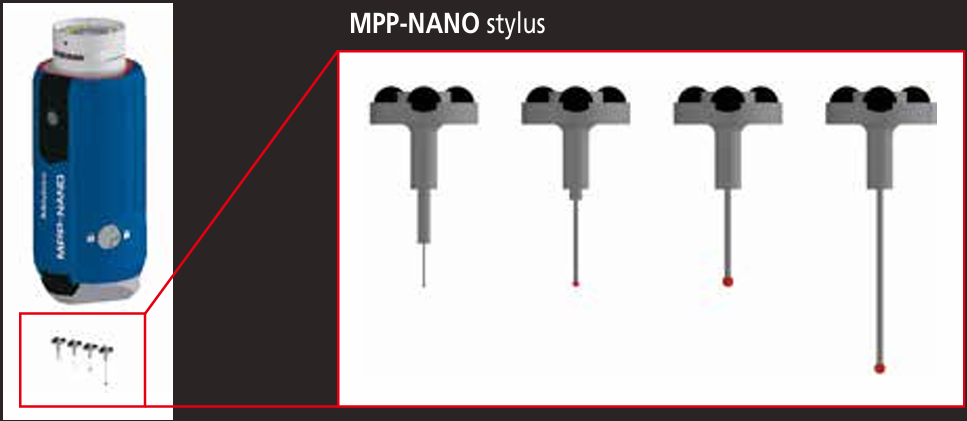

Newly developed MPP-NANO probe on which styli as small as 125 µm diameter can be mounted achieves autonomous scanning of fine detail.Using the observation camera, the approach to the workpiece can be easily performed while also checking for dirt and scratches on the workpiece. The highly proven SP25M scanning probe is also supported so the system can also be used for large workpieces as well as small.

Vision measurement functions provide high level performance

Uses the same image head as the Quick Vision series, the best-selling vision measuring system. Also equipped with the same optical system as the Quick Vision, multiple lighting functions and excellent evaluation software to provide high performance.

Measuring machine well suited to micro-form measurement

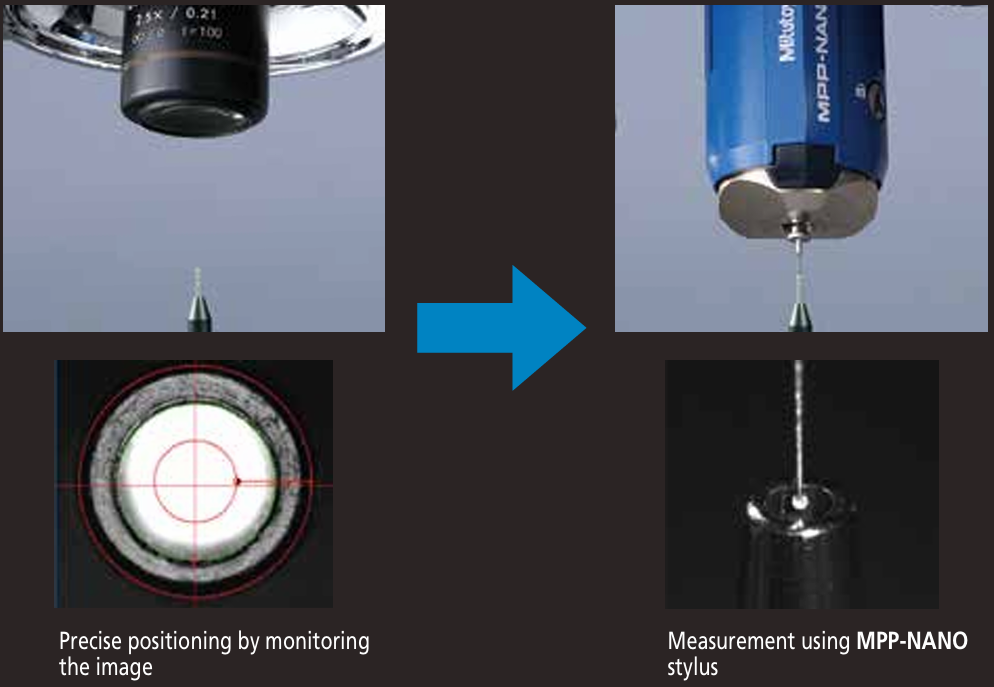

Ideal hybrid measuring machine with vision head and scanning probe (MPP-NANO, SP25M).The image head enables precise positioning and targeting measurement even in shrouded locations where visual checking is difficult.

|

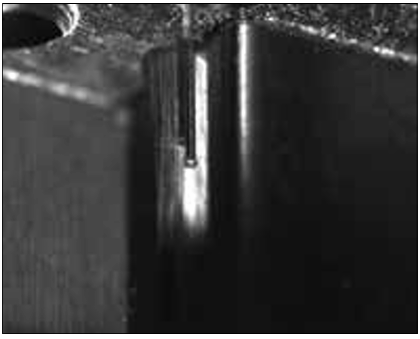

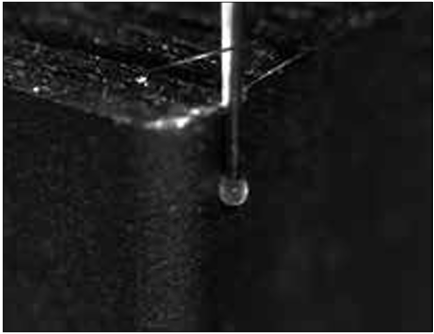

For the MPP-NANO stylus, an observation unit is available as an option. Even when using the extra small 0.125-mm-diameter stylus, checking on the monitor enables a safe approach to the measuring point.

|

A magnetic kinematic joint connection enables easy stylus replacement. Stylus replacement tools, which are in the MPP-NANO stylus tool kit, are supplied as standard.

|

In recent years, the need for fine-detail processing technology has been increasing rapidly, including the sensing technology essential for vehicle motorization and autonomous driving. Simultaneously, enabling high

accuracy, high-throughput measurement of microscopic form is required. Mitutoyo responded quickly to these needs, and started selling the Micro Form Measuring System UMAP Vision System some time ago. According to the current need for improving productivity, we have developed the MiSCAN Vision System, a measuring system capable of measuring micro form with the MPP-NANO, a small diameter scanning probe.

Examples of micro-form measurement achieved with the MiSCAN Vision System and MPP-NANO

Microscopic gear teeth

Conventionally, highly efficient scanning of microscopic gear teeth whose module is one or lower has been difficult. However, using the MiSCAN Vision System together with the MPP-NANO enables this scanning. Simply enter each nominal using GEARPAK, which is the gear teeth evaluation software, to easily evaluate the tooth profile error and tooth trace error.

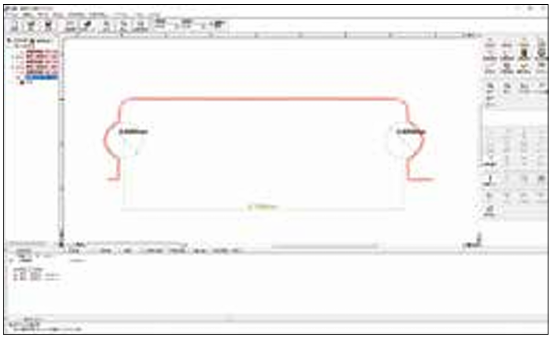

Module 0.8 master gear measurement Module 0.8 master gear measurement |

Measurement using the MPP-NANO 0.125-mm-diameter stylus Measurement using the MPP-NANO 0.125-mm-diameter stylus |

GEARPAK-Cylindrical analysis GEARPAK-Cylindrical analysis |

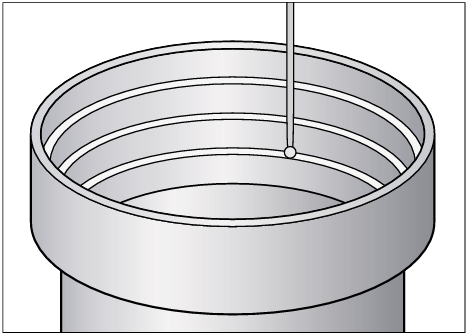

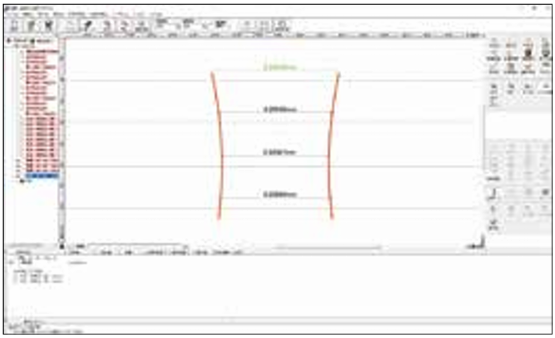

Lenses and optical tubes

The MiSCAN Vision System and MPP-NANO enables high-accuracy, highly efficient measurement of miniaturizing and evolving optical tubes. The MPP-NANO can measure the contour of high degree aspheric lenses used in the vehicle-mounted camera with high accuracy.

Optical tube Optical tube |

Aspheric-form MPP-NANO measurement Aspheric-form MPP-NANO measurement |

SCANPAK form analysis example SCANPAK form analysis example |

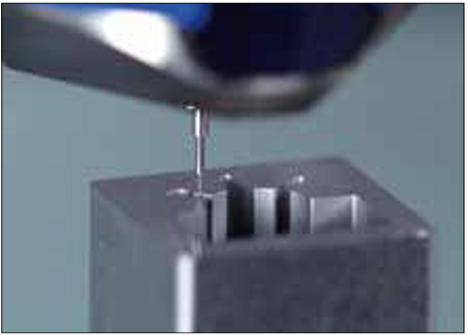

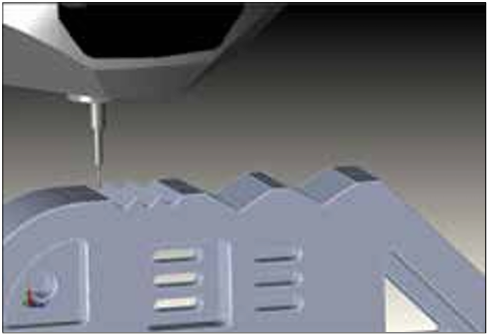

Precision molds

The MiSCAN Vision System and MPP-NANO enable scanning measurement of microscopic feature detail, such as precision punches and dies, using extra-small-diameter styli, which are available with diameters as small as 0.125 mm.

MPP-NANO mold scanning MPP-NANO mold scanning |

Image seen using the stylus observation camera unit Image seen using the stylus observation camera unit |

SCANPAK form-analysis example SCANPAK form-analysis example |

Precision mechanical parts

The MiSCAN Vision System and MPP-NANO enable highly efficient, high-accuracy measurement of miniature mechanical parts that improve precision in industrial machinery.

|

Precision mechanical parts (linear guide) |

Image seen using the stylus observation camera unit |

FORMTRACEPAK-AP form analysis example |

Micro-hole measurement

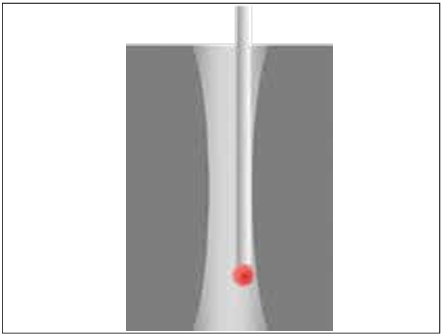

Conventionally, only destructive measurement was possible for the inner diameter of nozzles and draw dies. However, the MiSCAN Vision System and MPP-NANO now enable performing scanning measurement using the stylus on holes with a maximum aspect ratio of 17:1.

|

Maximum aspect ratio: 17:1 (for R500-125-85) |

MPP-NANO micro-hole measurement |

FORMTRACEPAK-AP analysis results FORMTRACEPAK-AP analysis results |

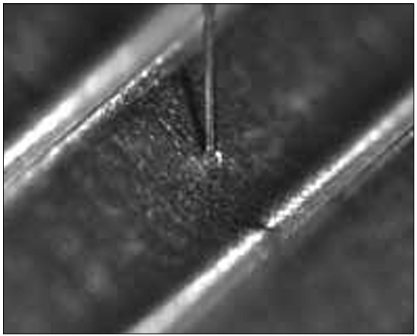

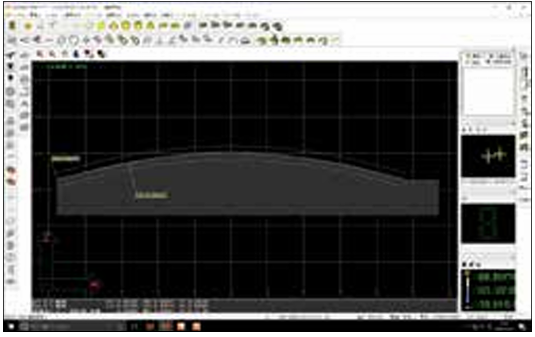

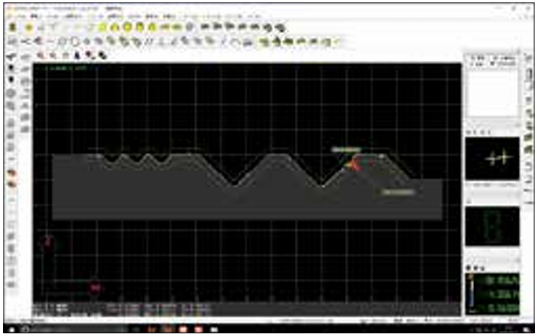

Fine detail contour analysis

Optional CAT1000S (optional) software enables nominal scanning measurement and form evaluation of micro V-grooves and rectangular grooves.

|

Micro V-groove |

Creating nominal sections from CAD data Creating nominal sections from CAD data (CAT1000S) |

SCANPAK design value verification SCANPAK design value verification |

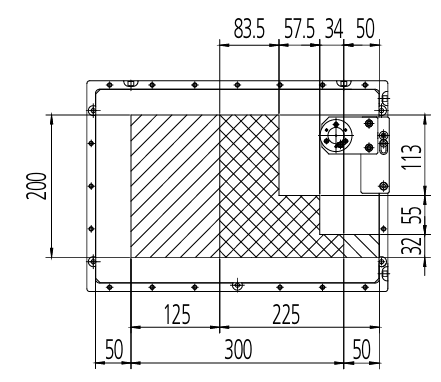

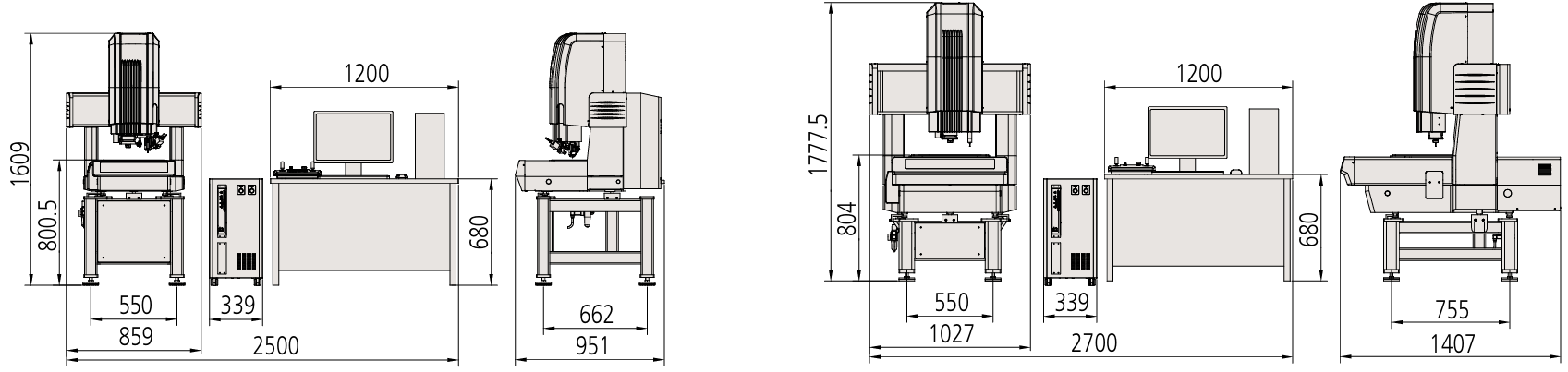

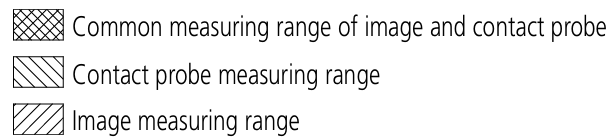

External dimensions and measuring ranges

|

|

|

|

|

|

|